bulk bag conditioner

A maintenance-free bag conditioning system to return a hardened big bag to a free flowing state

A maintenance-free bag conditioning system to return a hardened big bag to a free flowing state

PLC

Easy to use touch panel to process different sizes of big bags

Safety

Optical safety barriers operated by a SIL2 certified control unit

self supporting structure

Rigid frame with closed structure, it can be installed in small spaces

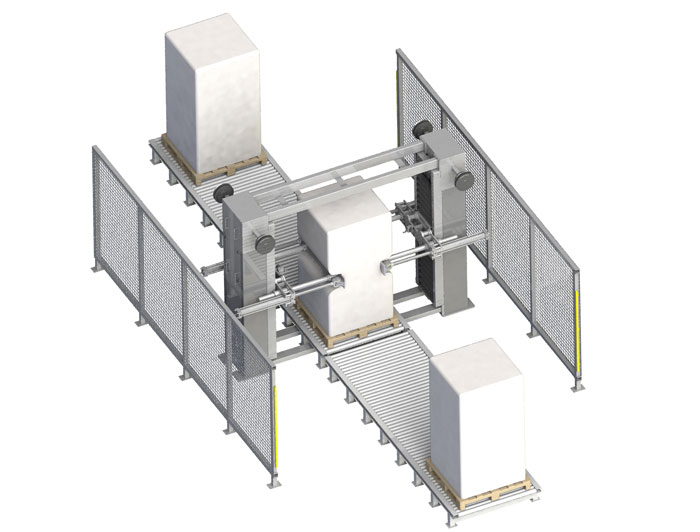

Gimat bulk bag reconditioning systems are available in two versions: a configurable modular version and a gantry frame version. The crushing plates perform the crushing action on the four side with adequate pressure, ensuring no damage to the big bag and guaranteeing an effective breakdown of hardened material for fast, free-flowing discharge.

Made of painted carbon steel or AISI 304 – 316 stainless steel on request, it is loaded via forklift or electric pallet truck. An efficient bulk bag conditioner it's the ideal preparatory step for the following bulk bag unloading station, that can be also equipped with lump breakers or vibratory screenings, if a check of final particle size or presence of foreign bodies are required.

ATEX - Explosion Proof Protected

On request the bulk bag conditioner can be manufactured in compliance with the Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21

Output: 8 bulk bags per hour (up to 12 per hour*)

90° pneumatic pallet rotator

Adjustable crushing force via pressure regulator – max 8 bar

Electrical control panel with Siemens PLC and 7'' colour HMI – Industry 4.0 ready

It is suitable for applications where the big bags have fixed dimensions, defined at the machine configuration stage

Three-level crushing, factory-set according to the type of big bag to be processed and the height of the crushing plate. A simplified version with two-level crushing also available for big bags consistently under 1 metre in height — a more cost-effective solution for this specific application.

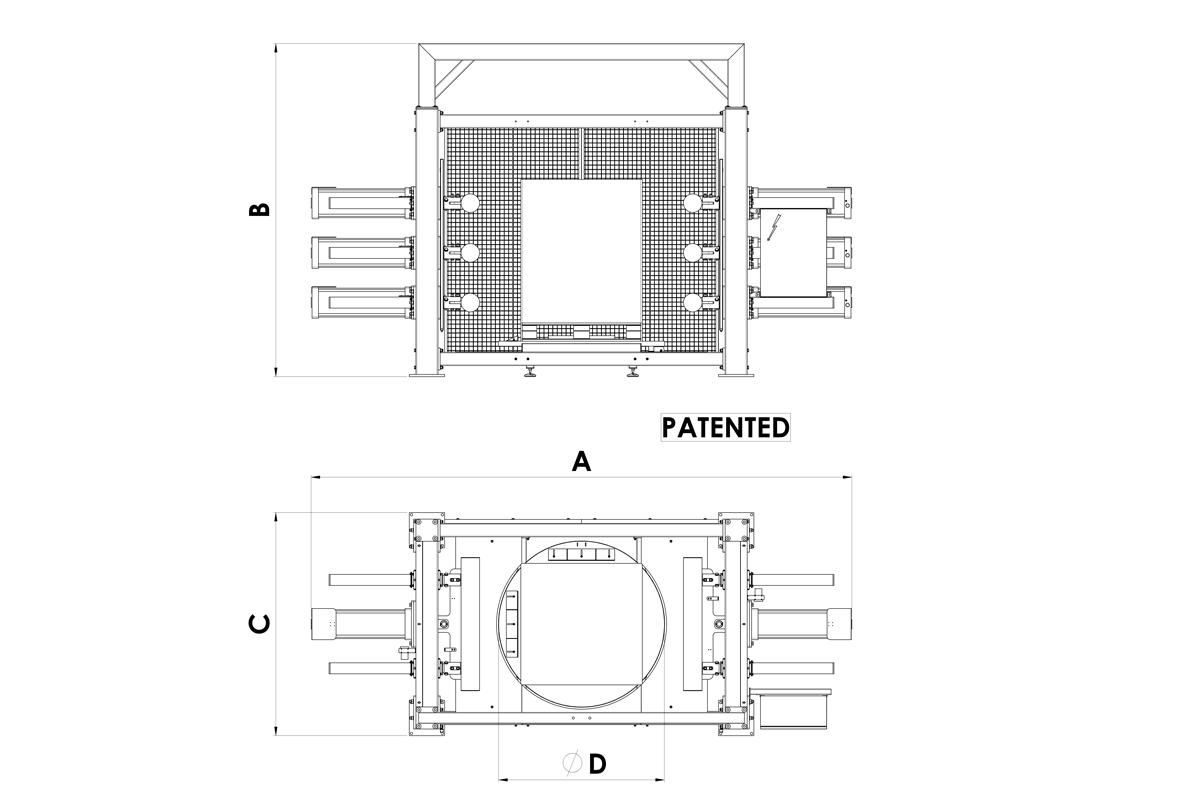

| Model | A | B | C | ØD |

|---|---|---|---|---|

| Pneumatic - Modular | 4900 | 3015 | 2020 | 1500 |

It’s the perfect solution if you need flexibility in changing big bag sizes and greater crushing force. Accurate, controlled crushing across the full height of the big bag

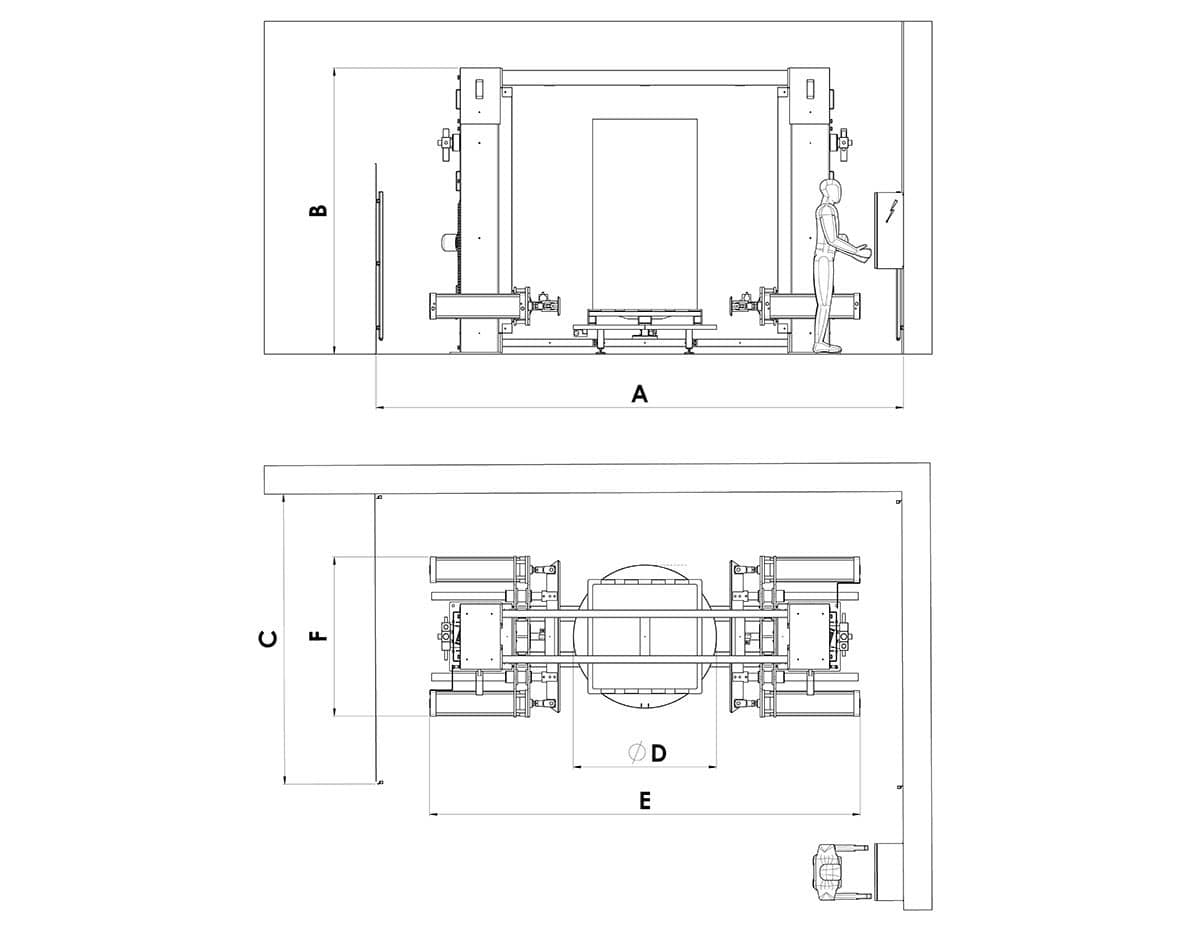

| Model | A | B | C | ØD | E | F |

|---|---|---|---|---|---|---|

| Electro-pneumatic | 5550 | 3012 | 3050 | 1500 | 4530 | 1675 |

Watch them at work

*To increase productivity up to 12 big bag per hour and reduce the big bag handling operations, our conditioning equipment can be integrated with a motorized rolling conveyor.

In the same product line see also:

Bulk bag filling equipment