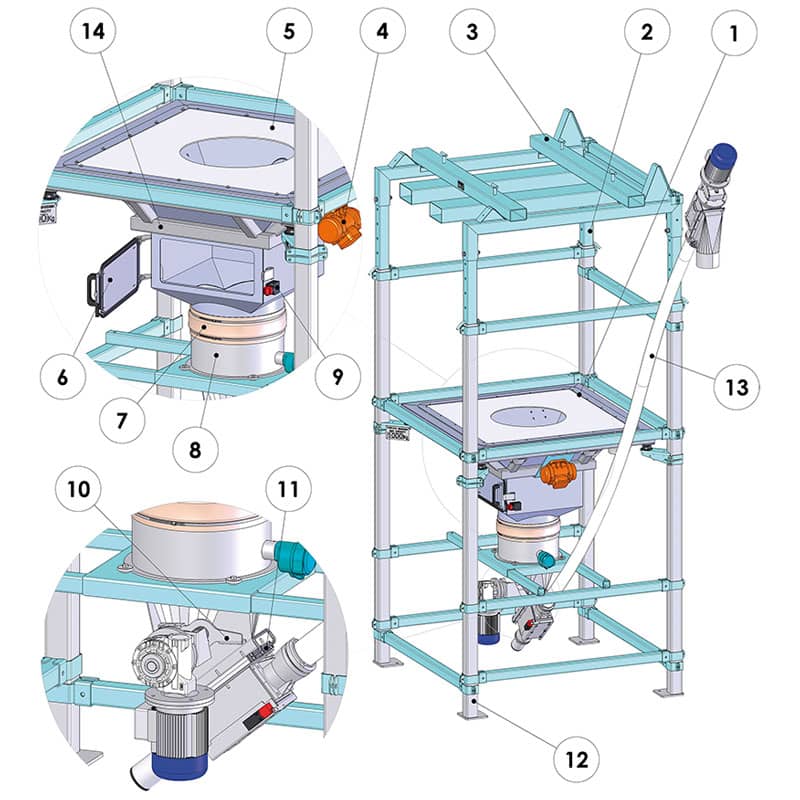

bulk bag unloader

Our standard and custom made bulk bag dischargers can be equipped with innovative accessories, to deliver high levels of efficiency

Our standard and custom made bulk bag dischargers can be equipped with innovative accessories, to deliver high levels of efficiency

Telescopic and fully bolted support frame

Easy to transport and assembly in restricted places. Easy to adjust the height to the dimensions of bulk bag

Discharge hopper

Made of antistatic polymer (FDA Approved), with electro-mechanical vibrator and rubber seal for dust free discharging

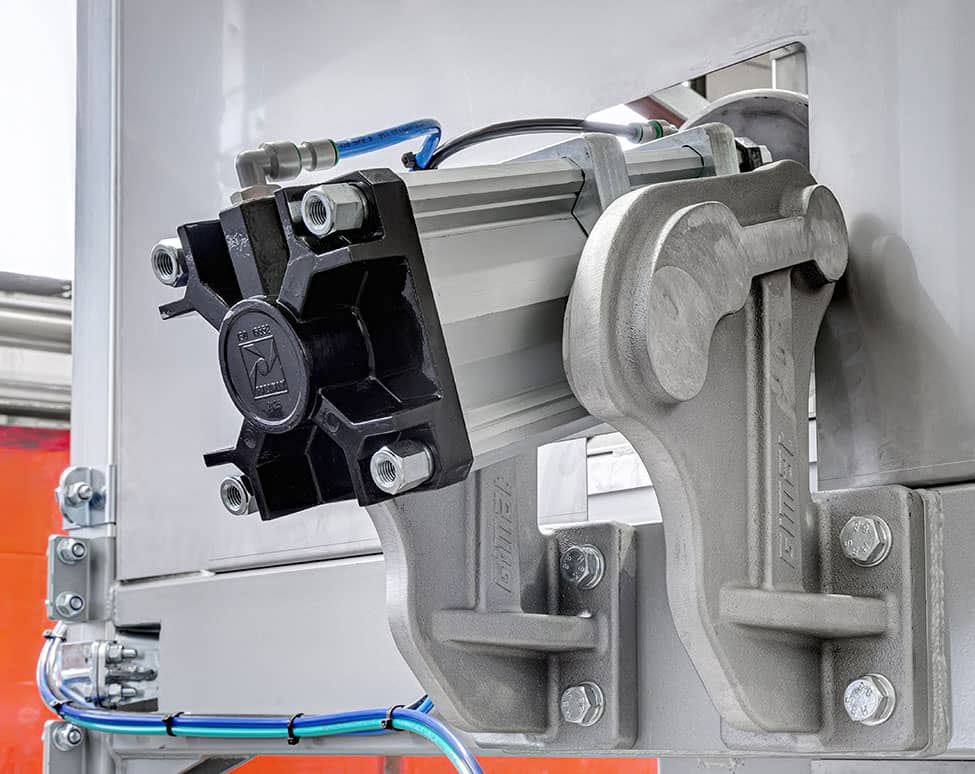

Air tight emptying system for harmful powders

On request pneumatic tightening system operating on bulk bag discharging spout

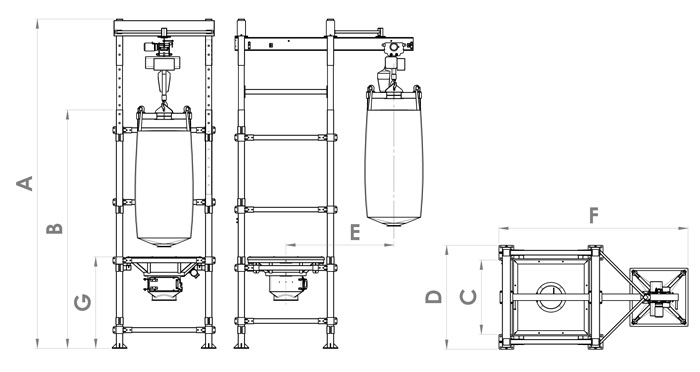

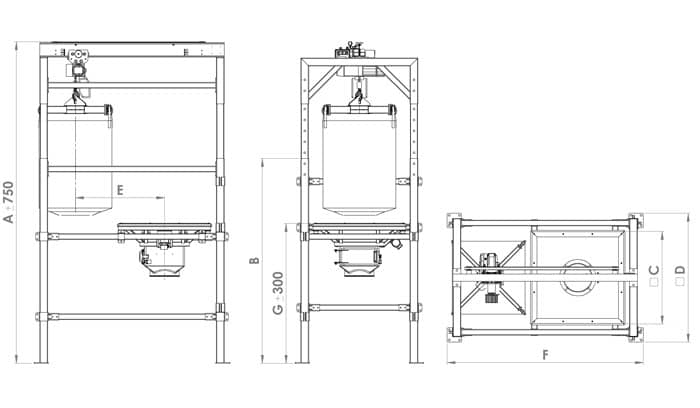

Gimat bulk bag unloaders have a telescopic design to adjust the height according to the big bag dimensions and a bolted support frame with junctions (registered Community design). Discharging hopper permits a safe open of the bulk bag for the operator in terms of mechanical risk and chemical risk. Our bulk bag unloading stations are manufactured in three different versions, depending on the available space and on the bulk bag lifting system used. The most common solution is with fork lift. When not possible the bulk bag is lifted with a crane system.

The big bag support structure in case of lifting by means of a hoist can be with portal beam or cantilever beam depending on the type of floor on which it is placed and on available foot space.

ATEX - Explosion Proof Protected

On request the bulk bag unloader can be manufactured in compliance with the Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21

Loss-in-weight system on load cells

To ensure precise and reliable dosing, this system applied on our bulk bag unloading stations measures weight loss during the batching cycle and send the information to the system controller.

Flat bottom extractor

To facilitate the flow of materials having poor fluency and the correct feeding of the mechanical or pneumatic conveying system under positioned.

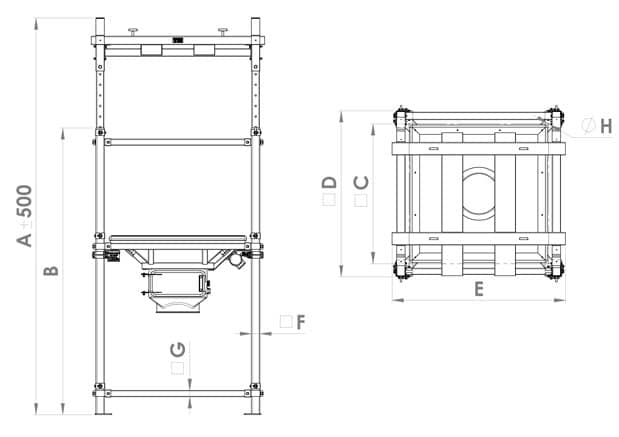

| Model | Max Load (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) |

|---|---|---|---|---|---|---|---|---|---|

| SSB.10 | 1000 | 3750 | 2710 | 1320 | 1570 | 1640 | 80 | 60 | 17 |

| SSB.15 | 1500 | 3750 | 2710 | 1320 | 1570 | 1640 | 80 | 60 | 17 |

| SSB.20 | 2000 | 3750 | 2700 | 1370 | 1620 | 1690 | 90 | 60 | 17 |

| Model | Max Load (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|

| SSP.10/20 | 1000/2000 | 5540 | 4012 | 1250 | 1750 | 1818 | 3180 | 1538 |

| Model | Max Load (kg) | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|

| SPR.10/20 | 1000/2000 | 4415 | 2812 | 1283 | 1770 | 1225 | 2696 | 1920 |

Watch them at work

Knife kit

Dust proof emptying

Load cells

You can also have a look at these pages on case histories