Ribbon mixer

A custom-built ribbon mixer run efficiently, provide higher output and require less maintenance

A custom-built ribbon mixer run efficiently, provide higher output and require less maintenance

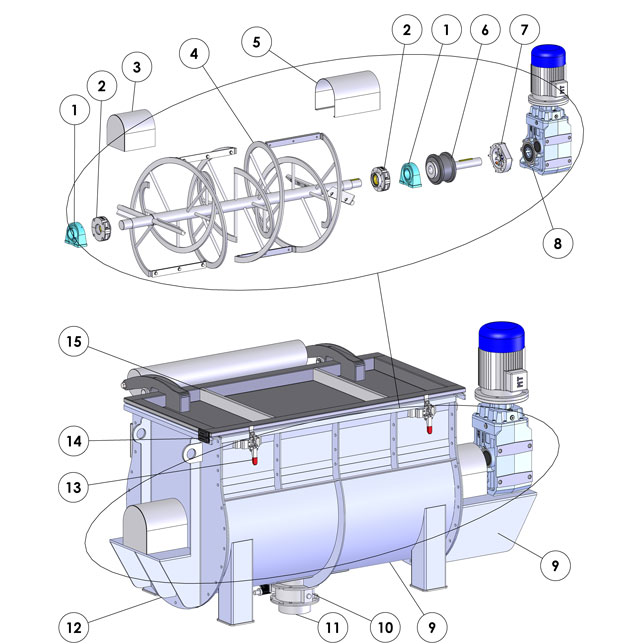

Gimat ribbon blenders are made of painted thick carbon steel sheets or stainless steel AISI 304 or 316 with suitable surface treatments. Our specially designed four-way ribbon - four cross-flows for the homogeneous blending of dry powders, granules and pastes.

Our ribbon mixers range from 340 to 3500 litres (power ratings, depending on the application, from 3 kW to 30 kW).

Among the ribbon blender manufacturers, Gimat stands out for the efficient transmission by means of a bevel gearmotor; a torsional flexible coupling offers high output for smooth and quiet operations. Designed to ensure fast, efficient blending, our ribbon mixers are appreciated for the longevity of performance. We design and manufacture custom powder mixers to cost-effectively meet your application requirement.

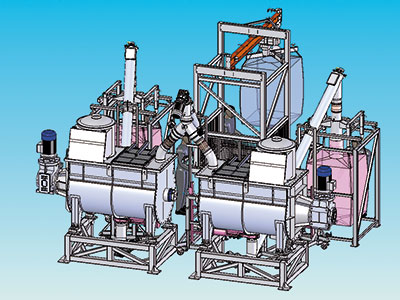

We also design complete bagging lines, from unloading from big bags to packaging, with equipment for mixing food powders.

ATEX - Explosion Proof Protected

On request our horizontal mixers can be manufactured in compliance with the Directive 2014/34/EU FOR ZONE 2-22 / ZONE 1-21.

Electric control panel

Safety coupling as torque limiter

Support frame

Load cell-weighing system

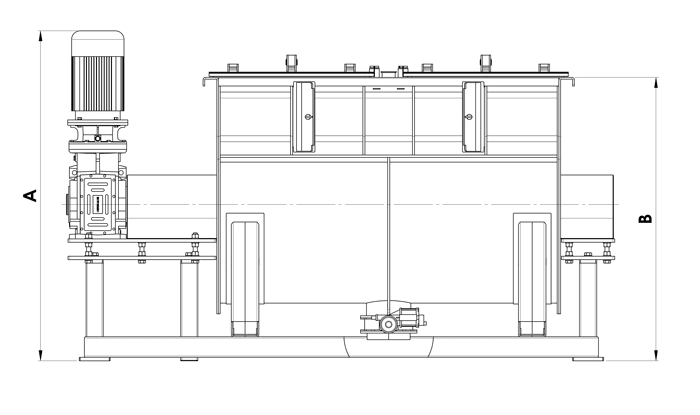

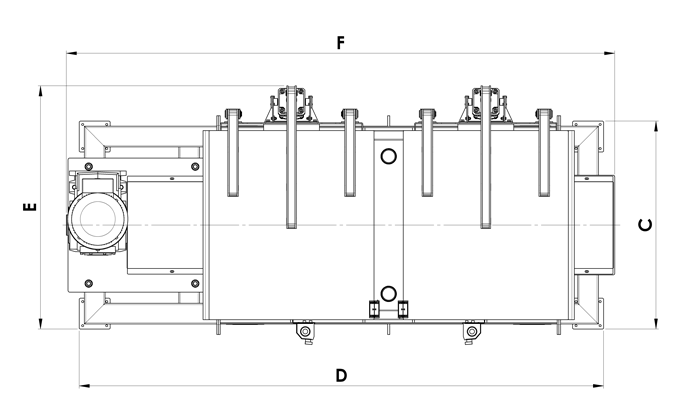

| Model* | Geometrical volume (lt) | Useful volume (lt) | Max charge (kg) | Gearmotor (kw) | A | B | C | D | E | F |

|---|---|---|---|---|---|---|---|---|---|---|

| HMX.340 | 425 | 340 | 340 | 3 | 1150 | 905 | 625 | 1010 | C=1025 MG=790 | 1870 |

| HMX.550 | 700 | 550 | 550 | 4 | 1290 | 1095 | 760 | 1220 | C=1140 MG=900 | 2060 |

| HMX.1000 | 1235 | 1000 | 1000 | 9.2 | 1570 | 1365 | 950 | 2640 | C=1310 P=1210 | 1020 |

| HMX.1500 | 1850 | 1500 | 1500 | 11 | 1660 | 1515 | 1080 | 2870 | C=1445 P=1330 | 2890 |

| HMX.2000 | 2515 | 2000 | 2000 | 15 | 1925 | 1650 | 1210 | 3050 | P=1445 | 3190 |

| HMX.3500 | 4455 | 3500 | 3500 | 30 | 2215 | 1810 | 1400 | 3880 | P=1655 | 3880 |

* other sizes on request

C = hatch opening with counterweight

P = hatch opening with Pneumatic Cylinder

MG = hatch opening with Gas Springs

To find out more about our technological capacity in the field of industrial mixing, also read this overview of our range of powder blending machines.

Equipment

System description: 2000 liter horizontal ribbon mixer, with pneumatic lids that can be fully opened for cleaning. The discharge takes place via a u-trough screw conveyor on wheels with opening lids for dry cleaning or washing with high-pressure cleaners and quaternary ammonium salts.