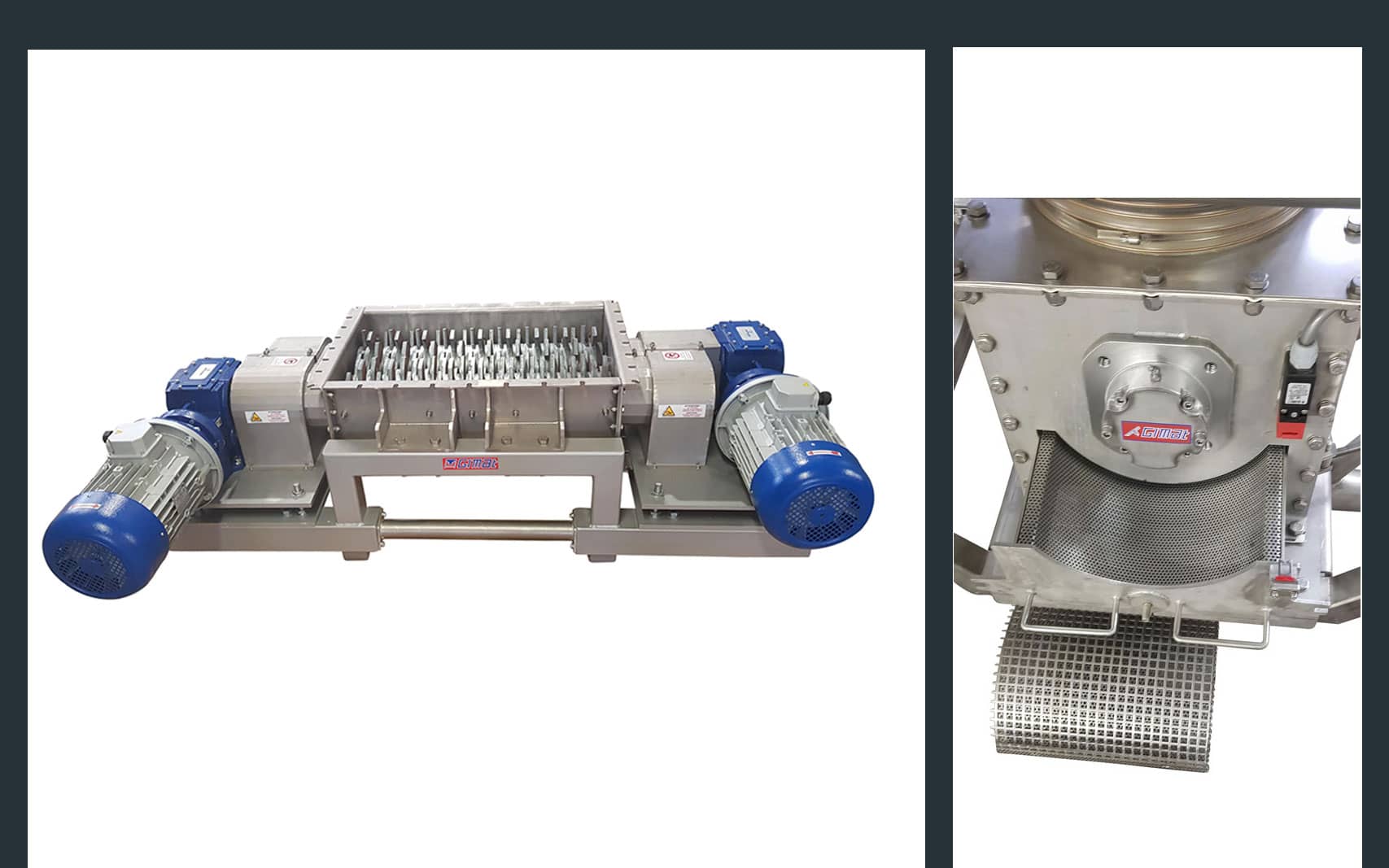

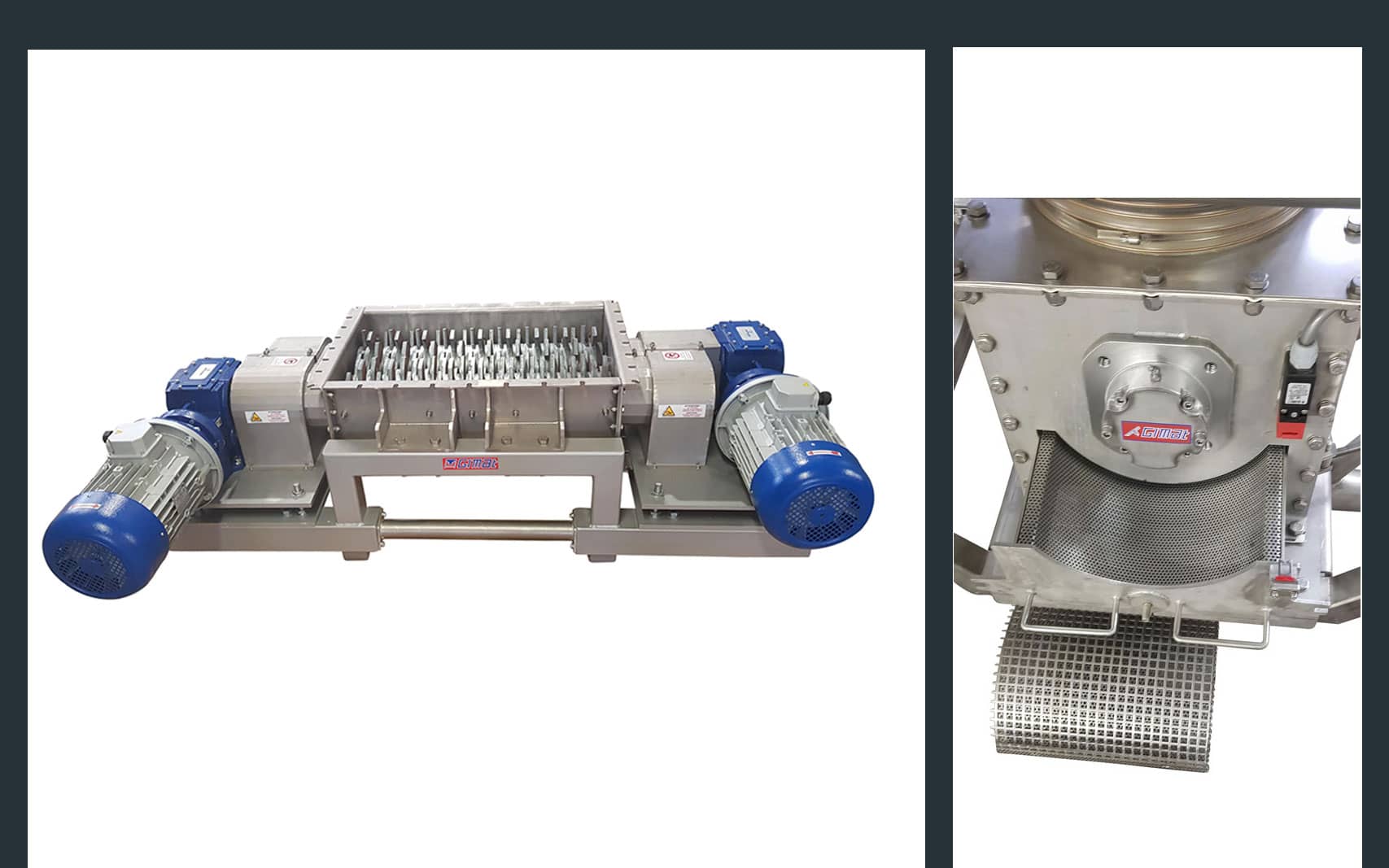

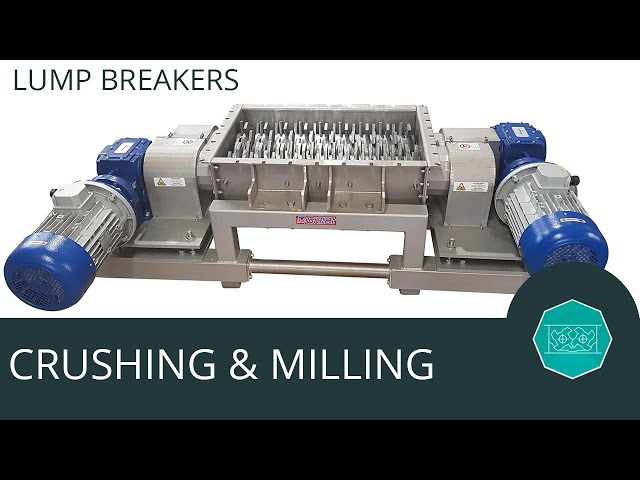

lump breakers

for breaking up lumps and aggregates in bulk solids and powders discharged from bulk bags, hoppers and bins

for breaking up lumps and aggregates in bulk solids and powders discharged from bulk bags, hoppers and bins

Gimat lump crushers are made of painted carbon steel or stainless steel Aisi 304 or 316. Special surface treatments can be applied for specific purposes to the blades, that are designed for the replacement of the single part in case of wear.

In order to grant a reliable mechanical transmission, all the lump breakers are equipped with a torsionally flexible coupling, bearings are protected by PTFE lip seals made on Gimat design. Available in 3 standard models and powers up to 6 kW or custom design and manufacturing.

ATEX - Explosion Proof Protected

On request Gimat lump breakers can be designed and manufactured in compliance with the Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21)

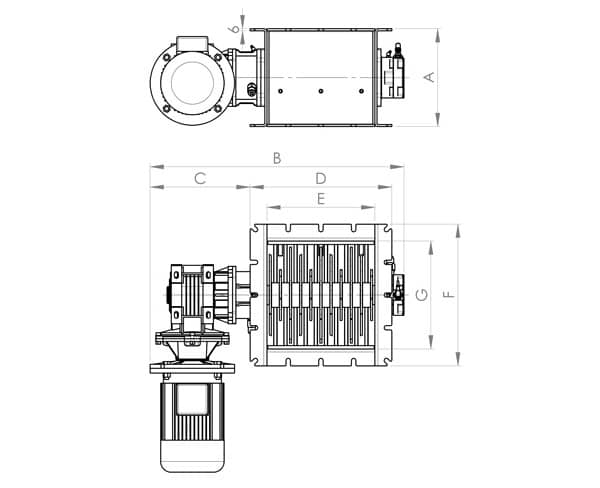

| model | shafts | m³/h | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) |

|---|---|---|---|---|---|---|---|---|---|

| RGM.2.5x2.5 | single | 15 | 290 | 619 | 253 | 330 | 250 | 330 | 250 |

| RGM.3x3 | single | 30 | 290 | 752 | 296 | 420 | 320 | 420 | 320 |

| RGM.5x5 | double | 90 | 290 | 948 | 341 | 600 | 500 | 600 | 500 |

| RGM.8x5 | double | 145 | 290 | 1510 | 296 -341 | 917.5 | 817.5 | 600 | 500 |

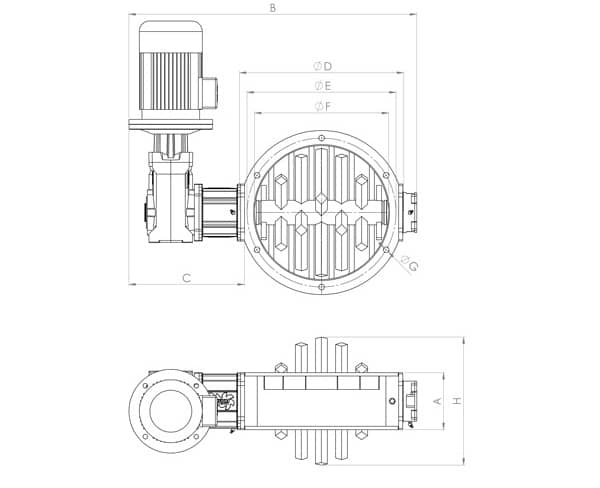

| model | shafts | m³/h | A (mm) | B (mm) | C (mm) | ØD (mm) | ØE (mm) | ØF (mm) | ØG (mm) | ØH (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RGM.D250 | single | 15 | 170 | 726 | 345 | 356 | 312 | 267 | M12 (4 holes) Ø13 (2 holes |

246 |

| RGM.D400 | single | 30 | 170 | 860 | 345 | 490 | 445 | 400 | Ø17 (6 holes | 246 |

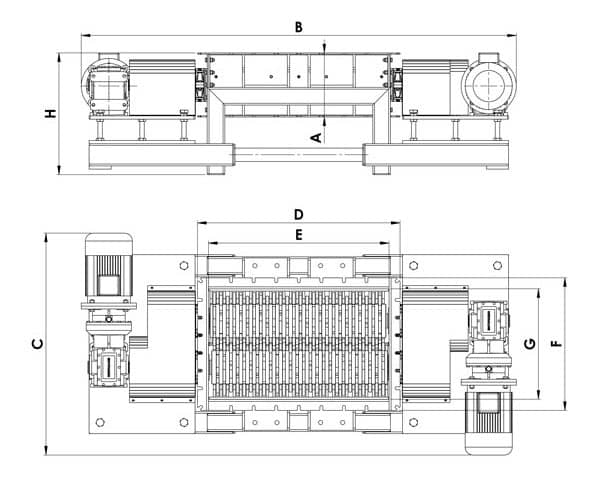

| model | shafts | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) |

|---|---|---|---|---|---|---|---|---|---|

| RGMHD.8x5 | double | 290 | 1970 | 1004 | 917,5 | 817,5 | 600 | 500 | 551 |

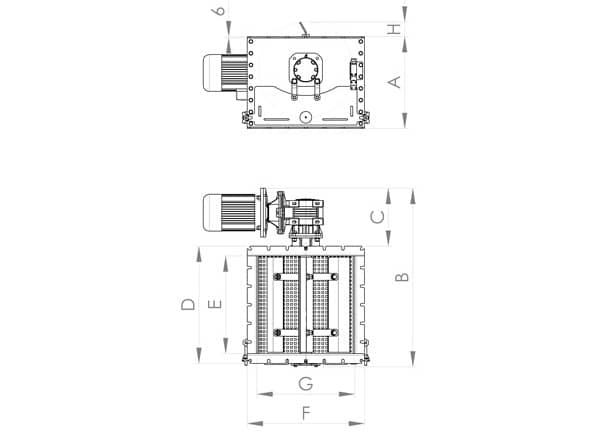

| model | shafts | mesh | A (mm) | B (mm) | C (mm) | D (mm) | E (mm) | F (mm) | G (mm) | H (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| RGMF.3x3 | single | on request | - | 752 | 296 | 420 | 320 | 420 | 320 | - |

| RGMF.5x5 | single | on request | 470 | 948 | 341 | 600 | 500 | 600 | 500 | 745 |

| RGMF.8x5 | single | on request | 470 | 1510 | 296-341 | 917.5 | 817.5 | 600 | 500 | - |

The shredder/finisher is an essential piece of equipment for reducing the size of product particles before they undergo further processing steps. This machine is typically installed alongside a lump crusher in a series or cascade arrangement. It not only aids in fine-tuning particle size but also serves a sieving function. For maintenance and cleaning, the control grids are easily removable and can be replaced based on the specific requirements of the product being processed. Furthermore, the shredder/finisher can function independently, without the need for a lump crusher, in scenarios where the lump content is minimal and the desired particle size variation between the input and output is not significant.

Hygroscopic powders absorb water from air humidity, increasing their cohesion and decreasing their flowability, that cause transport and storage difficulties. Salt, sugar, glucose, baking soda, citric acid, dextrose, calcium chloride are some of the more widely used as ingredients, additives, or processing aids in various food and chemical products and can exhibit hygroscopic properties.

In this application for hygroscopic powder we used a bag emptying hopper with hood for particulate exhaust. The lump breaker model RGM.8x5 (800 x 500 mm) boasts a double rotor configuration, enhancing flow rates and boosting crushing efficiency. The configuration is completed with the RGMF.8x5 finisher mounted in cascade under the lump breaker. Powder transfer via aeromechanical conveyor.

The shape of the knives, mesh size and motor powers are designed to suit the product.