mechanical screw conveyor

Use screw conveyors in a cost-effective way, overcoming constraints imposed by an existing or evolving plant

Use screw conveyors in a cost-effective way, overcoming constraints imposed by an existing or evolving plant

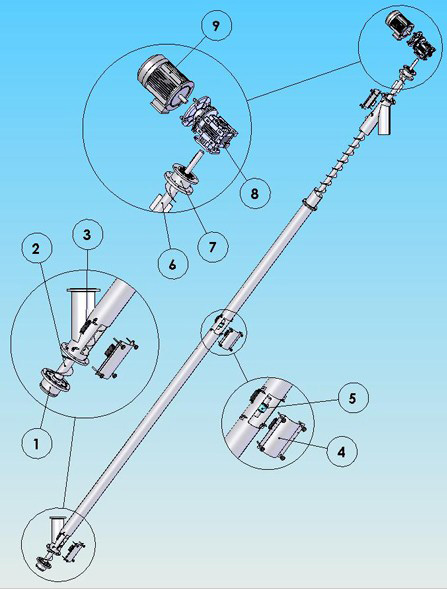

Dust sealing

Special system to reduce manual adjustments, minimize powder leaks

and grant an efficient dust protection of the thrust bearing units

FDA Approved Food Grade Lubricants

For long screw conveyors, over 4-5 metres, the intermediate support is made of

a self-lubricating material, FDA approved for direct food contact

High flow rates, robust design, versatility and low maintenance made the screw conveyor a very popular choice for bulk material handling. Can be employed in horizontal, inclined and vertical installations, they can be used to control the bulk material flow and the batching accuracy or as mixers to blend ingredients. The stainless steel versions are suitable for conveying food products, chemical and pharmaceutical.

ATEX - Explosion Proof Protected

All Gimat screw conveyors are available ATEX rated for use in explosive atmospheres (Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21).

| Model | Outside diameter | RPM Max | Output m³/h | Bulk Density Kg/m³) | Output (Kg/h) |

|---|---|---|---|---|---|

| TC.129/100 | 129 | 180 | 3,66 | 0,6 | 2200 |

| TC.139/100 | 139 | 180 | 6,66 | 0,6 | 4400 |

| TC.154/130 | 154 | 180 | 8,33 | 0,6 | 5000 |

| TC.168/140 | 168 | 180 | 10,33 | 0,6 | 6200 |

| TC.219/180 | 219 | 160 | 21,66 | 0,6 | 13000 |

| TC.273/250 | 273 | 130 | 41,66 | 0,6 | 25000 |