Gimat's line of rotary valves for material handling applications offers a comprehensive solution to regulate the flow of dust, powder and granular products with utmost precision. Building on our expertise in the field, we have introduced a range of rotary feeders that can be seamlessly integrated into existing installations or purchased separately. This new, patented model is available in the sizes DN 150, 200, 250 and 300.

ATEX - Explosion Proof Protected

Gimat AISI 304 or 316 stainless steel rotary valves are designed and manufactured in compliance with the Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21 and MOCA 1935/2004.

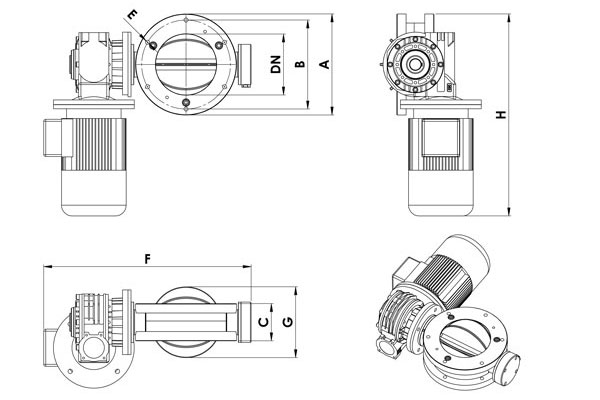

| model | dn | ØA (mm) | ØB (mm) | C (mm) | E (mm) | F (mm) | G (mm) | H (mm) | sectors | sector capacity | useful capacity | temperature range | operating pressure |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rv150 | 150 | 250 | 220 | 92 | 6*m12 | 514 | 175 | 456 | 8 | 0.35 L | 2100 L/h | -20°C to +100°C, optional +150°C | -0,8 barg to +0,8 barg |

| Rv200 | 200 | 300 | 270 | 92 | 6*m12 | 564 | 220 | 485 | 8 | 0.64 L | 3840 L/h | -20°C to +100°C, optional +150°C | -0,8 barg to +0,8 barg |

| Rv250 | 250 | 350 | 320 | 112 | 6*m12 | 618 | 273 | 591 | 8 | 1.3 L | 7800 L/h | -20°C to +100°C, optional +150°C | -0,8 barg to +0,8 barg |

| Rv300 | 300 | 430 | 400 | 130 | 6*m16 | 724 | 326 | 610 | 8 | 2.1 L | 12800 L/h | -20°C to +100°C, optional +150°C | -0,8 barg to +0,8 barg |

| feature | Gimat rotary valve | Standard rotary valve |

|---|---|---|

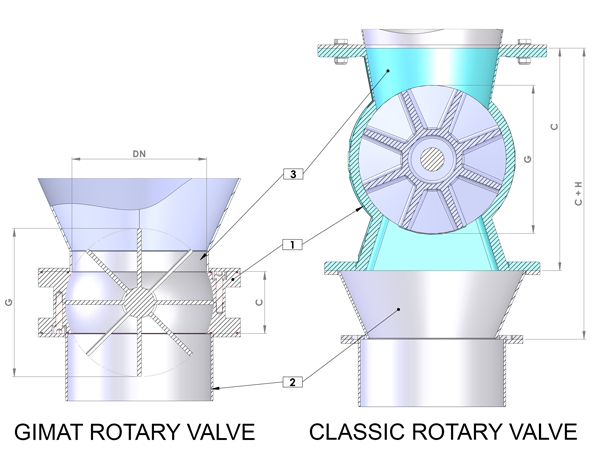

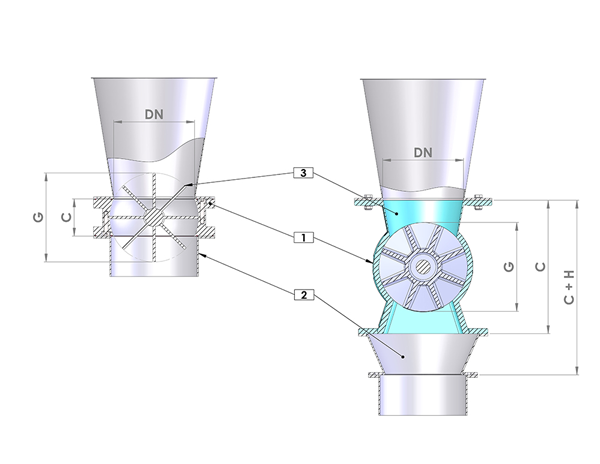

| dimensions | Compact and lightweight | Large size |

| Connection | Upstream and downstream direct connection by round flange | A manifold is required to adapt from square to round flange |

| Bridge-breaker | Entering the upper carpentry, the rotor also has a bridge breaker function, to facilitate material withdrawal | The rotary valve doesn't act as a bridge breaker |

Useful flow rate: from 2 to 13 m3/h

For those requiring precise dosing capabilities, our rotary valves can be easily controlled using an inverter

Easy cleaning and maintenance, thanks to the compact and lightweight body, featuring a protruding rotor

Specifically crafted for pneumatic conveying systems operating under either depression (maximum -0.8 barg) or low pressure (maximum +0,8 barg).

With round flanges at the inlet and outlet, our rotary valves are particularly well-suited for vertical installations

It can be easily converted into a blow-through rotary valve by adding a sleeve at the bottom, connected to the pneumatic conveying pipeline.

In the same product line see also:

Lump breakers

Several chemical companies have frequently expressed shared needs in optimizing powder transport to dissolvers, prompting us to develop an ideal solution tailored to these specific requirements. Below are the key objectives we addressed in designing our system:

With our rotary valves ensuring vacuum integrity within the system, this solution incorporates best practices and cutting-edge technologies to comprehensively address industry requirements, ensuring efficiency, safety and operational flexibility. Read more about this: Gimat rotary valves for feeding dissolvers.

In the chemical and plastics industries, controlling the dispersion of powder in the working environment is a common challenge faced by many companies. Recognizing the widespread need for solutions in this area, we have developed systems specifically designed to address these critical requirements:

We present an example of this solution implemented with our rotary valve, designed to achieve a flow rate of 4000 kg/h over a conveying distance of 60 meters while effectively containing powder dispersion. Further details about this application are available on the project page Gimat rotary valves for powder containment.

In the food industry, precise handling of powdered materials is essential to ensure efficiency, cleanliness and product quality. An effective system integrates a Big Bag unloading station equipped with a vibrating hopper and a dust-tight seal at the bottom of the Big Bag. The rotary valve, positioned below the hopper and above the centrifugal sieve, plays a critical role in maintaining vacuum integrity, accurate dosing and reliable pneumatic conveying downstream.

This solution provides a reliable and hygienic system for powder handling, integrating dust control, precise dosing and efficient pneumatic conveying. For a detailed example of its implementation in a food production facility, visit the dedicated project page. Gimat rotary valves - compact vertical placement.

The customer needed to replace an old rotary valve that was having leakage problems due to excessive wear.

The existing solution was also unable to guarantee with some of the dust extracted a regular flow of product to the outlet of the cyclone filter due to the dust being compacted in the lower part of the cone.

The GIMAT rotary valve, thanks to the unique design of its rotor blades protruding inside the cyclone - cone and the reduced clearances between the rotor and the valve body, made it possible to solve both problems with a single machine.

GIMAT's flexibility in making the connection flanges both upstream and downstream of the rotary valve made it possible to provide the customer with a complete solution within a short timeframe.