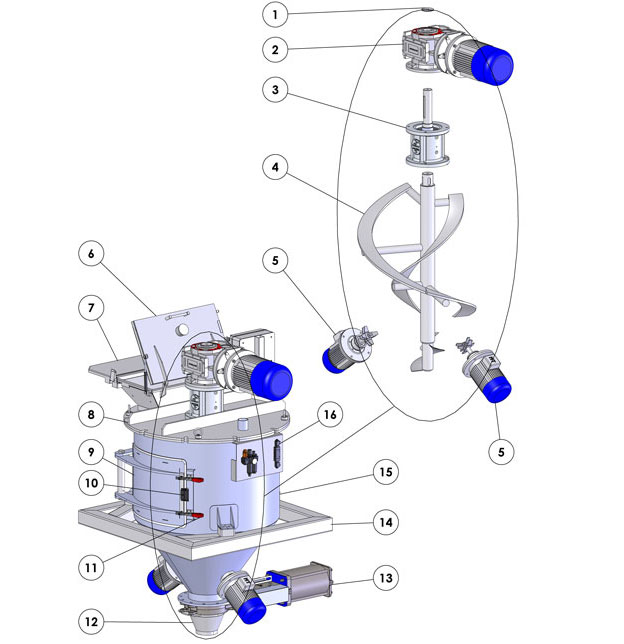

Vertical ribbon blender

Vertical blenders for food and pharmaceutical industry for fast, gentle and uniform mixing

Vertical blenders for food and pharmaceutical industry for fast, gentle and uniform mixing

An industrial mixer is used for mixing and blending of dry bulk materials, to obtain an homogeneous ouptut product, in a large number of industries, such as food, chemicals, plastics, pharmaceutical. The mixing equipment very often must be specifically engineered for the type of product, the mixing requirements and the specific application. Therefore a mixer manufacturer must have extensive experience in testing and designing machines for the powder mixing processes, performed at different temperatures or pressures.

Industrial blenders and mixers that use the latest technolgy can maximize the efficiency and can be integrated with modern production control systems. And a powder mixing machine especially in the food and chemical industries must comply with strict safety standards. Gimat industrial mixers meet both needs.

Our proprietary technology allows us to maintain a complete control over the quality of components and ensures the reliability of Gimat powder mixers.

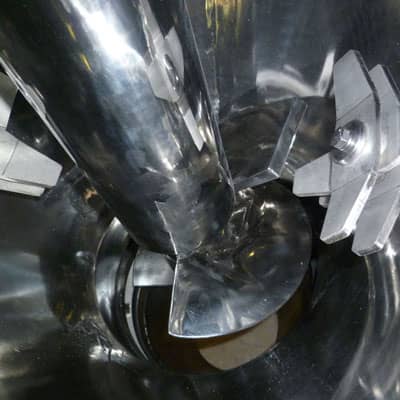

Thanks to the special helicoid shape, the mixing process is faster and more homgeneous compared to traditional vertical powder mixers, especially at the centre of the mixing chamber. A die-cast food grade aluminum frame with two large ball bearings creates an effective joint for the mixing shaft.

The rotation of the helicoid creates two crossed flows:

Our industrial blenders have smooth surfaces that facilitate the elimination of residue during emptying and ensure easy maintenance and cleaning.

The powder mixing is gentle, without overheating the mixed product. A conical ribbon blender can be used as homogenizer of the same powders but of different batches. In our vertical powder mixer, vacuum mixing is also possible for pneumatic loading, to create a continuous high-flow pneumatic conveying system for powders.

ATEX - Explosion Proof Protected

Our vertical industrial blenders are suitable for use in explosive atmospheres (Directive ATEX 2014/34/EU FOR ZONE 2-22 / ZONE 1-21).

Low peripheral speed (recommended for for applications in hazardous areas)

It can be equipped with high pressure washing nozzles

Silent running operation (mixing shaft rotation by bevel gearmotor)

No residue (fine finishing of internal surfaces)

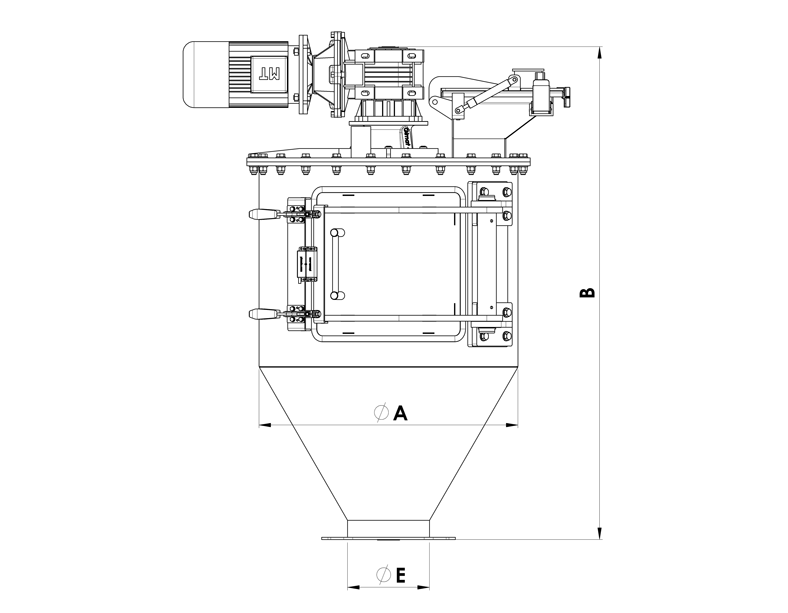

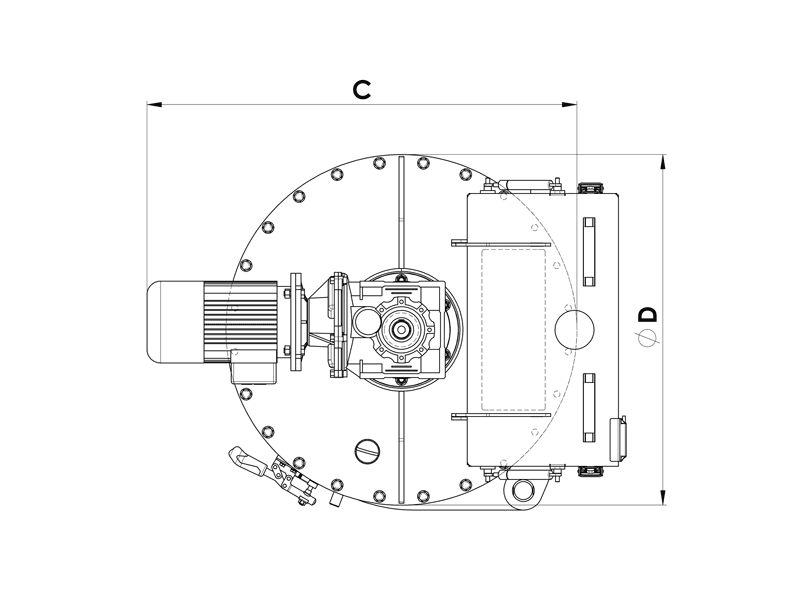

| Model* | Geometrical volume (lt) | Useful volume (lt) | Max charge (kg) | Gearmotor (kw) | A | B | C | D | E |

|---|---|---|---|---|---|---|---|---|---|

| VMX.100 | 105 | 100 | 100 | 1.5 | 654 | 970 | 890 | 720 | 200 |

| VMX.200 | 230 | 200 | 200 | 2.2 | 658 | 1255 | 970 | 720 | 200 |

| VMX.340 | 430 | 340 | 340 | 3 | 808 | 1405 | 1045 | 920 | 200 |

| VMX.600 | 650 | 600 | 600 | 5.5 | 1008 | 1720 | 1330 | 1150 | 200 |

| VMX.1000 | 1200 | 1000 | 1000 | 7.5 | 1108 | 2020 | 1330 | 1250 | 250 |

* other sizes on request

Equipment

System description: for mixing tasks with liquid addition, in this mixing machine, a diaphragm pump adds the liquid flavour; the unit is complete with a lump breaker to avoid the formation of agglomerates and for a better spread of the flavour. Emptying and transport without demixing by means of a portable screw conveyor on wheels, "easy-to-clean" version.

Equipment

Customer:

System description: Vertical mixing unit with a capacity of 600 liters complete with a double lump breaker for mixing hygroscopic powder fertilizers. To pack the product, an auger filler for bags and cans is provided. Control panel for integrated system logic.

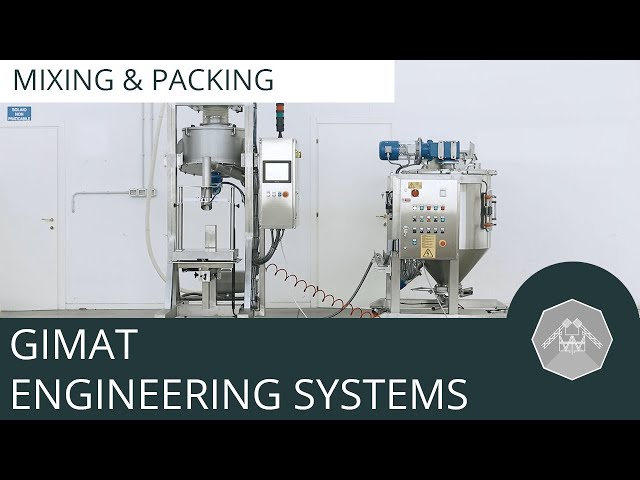

In this video we show you an equipment engineered for an ice cream powder mixes supplier, consisting of a vertical ribbon mixer and a bag filling equipment.

vertical ribbon mixer 200 lt

vertical ribbon mixer 1000 lt

If you are looking for industrial blenders for sales in UK, please contact our offices in Stoke on Trent