Dust collection and pneumatic transport: an integrated solution

Customers: companies in the chemical and plastic industry

Customers requirement: in the chemical or plastics industry, effective dust management is essential for operational efficiency and safety. A customer was faced with the challenge of implementing a dust handling system that was integrated to contain system costs and the control of dust dispersion in the environment with a pneumatic transport over a distance of 60 meters, to achieve a flow rate of 4000 kg/h in the transfer phase with the introduction of a GIMAT rotary valve.

Implemented solutions

GIMAT's solution included the following key components:

- Ergonomic hopper for emptying bags with containment hood:

- Features: large hopper with dust hood with suction connected to the piping of the pneumatic transfer system and using a special shut-off valve when the bags were not being emptied.

- Advantages: improvement of air quality and operator safety, limiting chemical risk and the recovery of dust generated during the opening of the bags.

- Pneumatic conveying system with 16.5 kW side channel turbine generating - 350 mbar vacuum:

- Specifications: operates up to -350 mbar with air flow rates of up to 1100 m3/h.

- Advantages: allows you to overcome the significant pressure drops that are generated during transfer at a distance of 60 metres, ensuring a yield of 4000 kg/h and at the same time sufficient air flow when used to capture dust inside the containment hood.

- Teflon-coated bag filter (20 m² Filtration Area):

- Features: resistant to humidity and easy to clean using cleaning reserved compressed air jets.

- Advantages: allows you to overcome the significant pressure drops that are generated during transfer at a distance of 60 metres, ensuring a yield of 4000 kg/h and at the same time sufficient air flow when used to capture dust inside the containment hood.

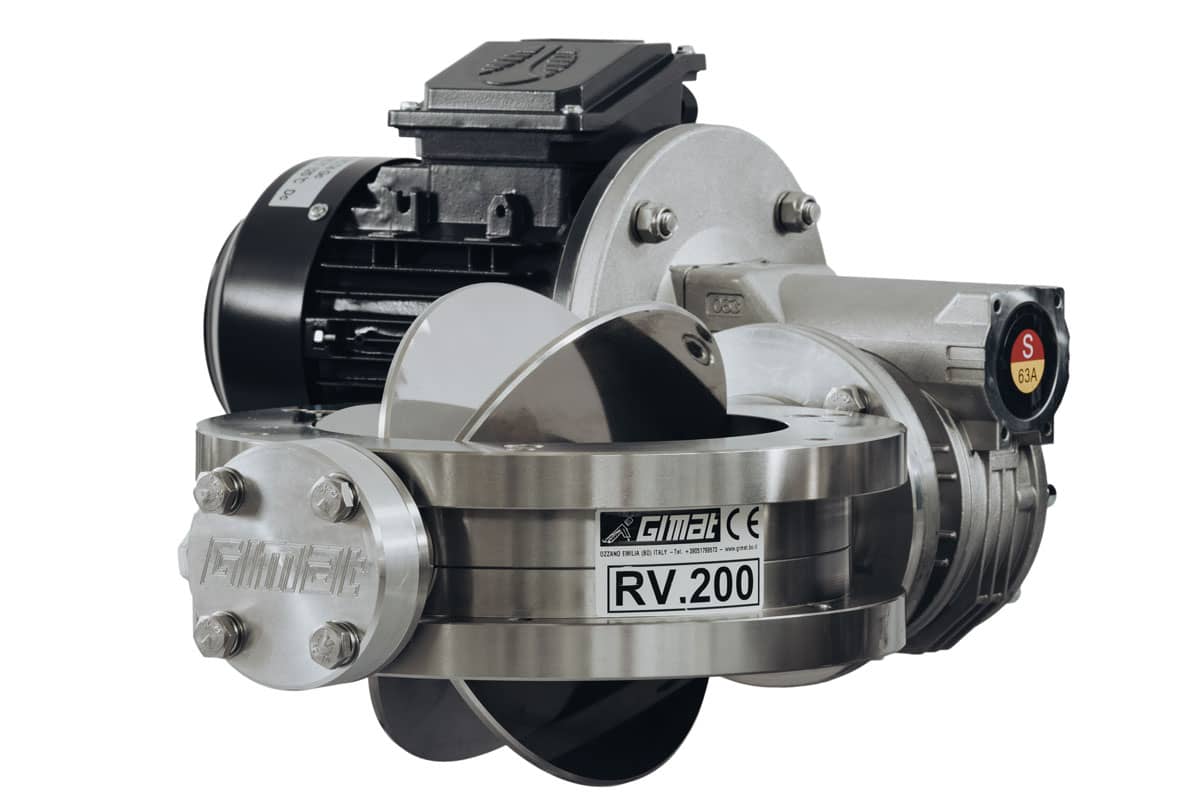

- GIMAT DN 200 rotary valve:

- Functionality: the GIMAT rotary valve with speed control sensor, allows the system to operate continuously compared to the traditional discontinuous one, maximising its flow rate.

- Advantages: our rotary valve with very low leakage thanks to the spherical body, has allowed the turbine's vacuum potential to be fully exploited. The innovative protruding rotor improved the regularity of the outgoing powder flow and eliminated machine downtime due to typical blockages in the cyclone cone, especially in exterior applications subject to humidity.